In general, the firebox can be smaller than you think. Take a look at really large smokers like the ones Aaron Franklin buids, and there you will see the firebox is relatively small. There are various suggestions online to make the firebox a certain percentage size of the food chamber, but that simply doesn’t hold true. Why not, you may ask? Well, the heat energy in burning wood is so high that even a 4-5 log fire can sustain temps in a 1000 gallon smoker. The size of the firebox is not related to the size of the food chamber. The purpose of the firebox is to create a fire that can warm up and hold temp in the food chamber. The firebox needs good oxygen supply, and should have room for building a good fire with 5-6 logs. This is to get more cooking capacity, but the temps will also be a little different (hotter on the higher grates), and this can be advantageous when smoking different cuts of meat at the same time. Regardless of size, two shelves/grates are recommended. Make sure you measure height also to get a correct vertical distance between shelves. I usually measure briskets and ribs with a folding rule to be able to estimate shelf size. Several grates at different levels are very common, as well as different door mechanisms. What style of smoker are you looking for? How much food do you need to cook at once? Size and shape is governed mainly by two things: Start with the food chamber and calculate the rest of the smoker accordingly. That is way less than most reverse flow smokers commercially available. My offset smoker ‘Rude Boy’ is a normal flow smoker, and I have a 5-8 degree temp variance in the food chamber. A well constructed offset smoker has no issues with temp swings. I think that is largely due to the many cheap offset smokers available on the market, which are badly designed and have large temp swings.

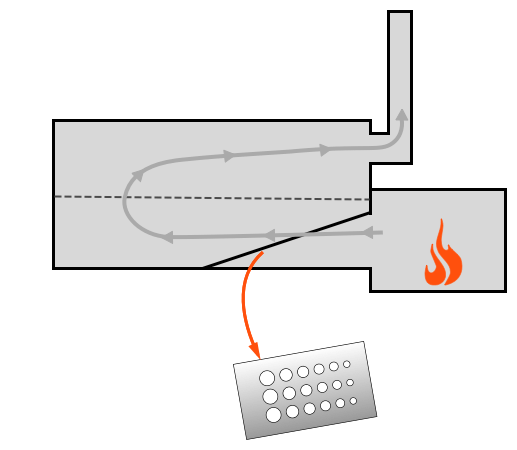

And that without even having used one, reverse flow or not. NOTE: many first time builders I talk to have their mind set on building a reverse flow smoker since they just ‘know’ it is better. You get slightly more even temps with the reverse flow in a small smoker. That being said the reverse flow design suits smaller smokers better since the BTU (energy) in is wood high. If unsure of which to build, start with a normal offset smoker, due to a simpler construction. One must remember that air moves a lot faster through an offset smoker than in your ordinary kettle or kamado. This distributes heat more evenly when it enters the food chamber. The hot air flow is slightly redirected by the smaller holes at the top, forcing some of the hot air down where the larger holes are. A common way to solve this is to use a slanting baffle perforated with different size holes.

Completely depending on different constructions an offset smoker is typically hotter the closer to the fire you get. The main idea behind reverse flow is (as mentioned) to reduce temperature differences in the food chamber. Reverse Flow Offset Smoker with perforated baffle

0 kommentar(er)

0 kommentar(er)