As Michael Klein, Terex Cranes manager product marketing, explains, nearly every country has specific axle load and axle spacing regulations. In Europe, two- to three-axle models popular, largely because of strict and varying road regulations, which is a hindrance for worldwide operation. In addition, the company has focused on simple designs for operation and maintenance, which makes them popular in developing markets where operators and high tech mechanics can be difficult to find.Ĭurnutte adds, “All terrain cranes are an ideal choice when soft, uneven terrain and steeper grades exist and they can reduce costs in those situations, compared to other mobile crane types that might experience mechanical issues or accelerated wear in those same conditions.” As Rick Curnutte, Link-Belt product manager for telescopic truck and all terrain cranes, explains, Link-Belt has designed both of its all terrain cranes, the ATC-3210 and ATC-3275, to be available with Tier III engines for different regions of the world. To meet demands, manufacturers tend to offer different engines and other technologies for different parts of the world. This versatility means that manufacturers need to design models that suit not only a wide range of industries, but a range of markets as well.

#Atc 3210 crane manual#

Centralised lubrication with manual override is available.Applications for all terrain cranes can be stretched from infrastructure projects to the energy sector, including wind turbine erection and maintenance, or even road building projects.

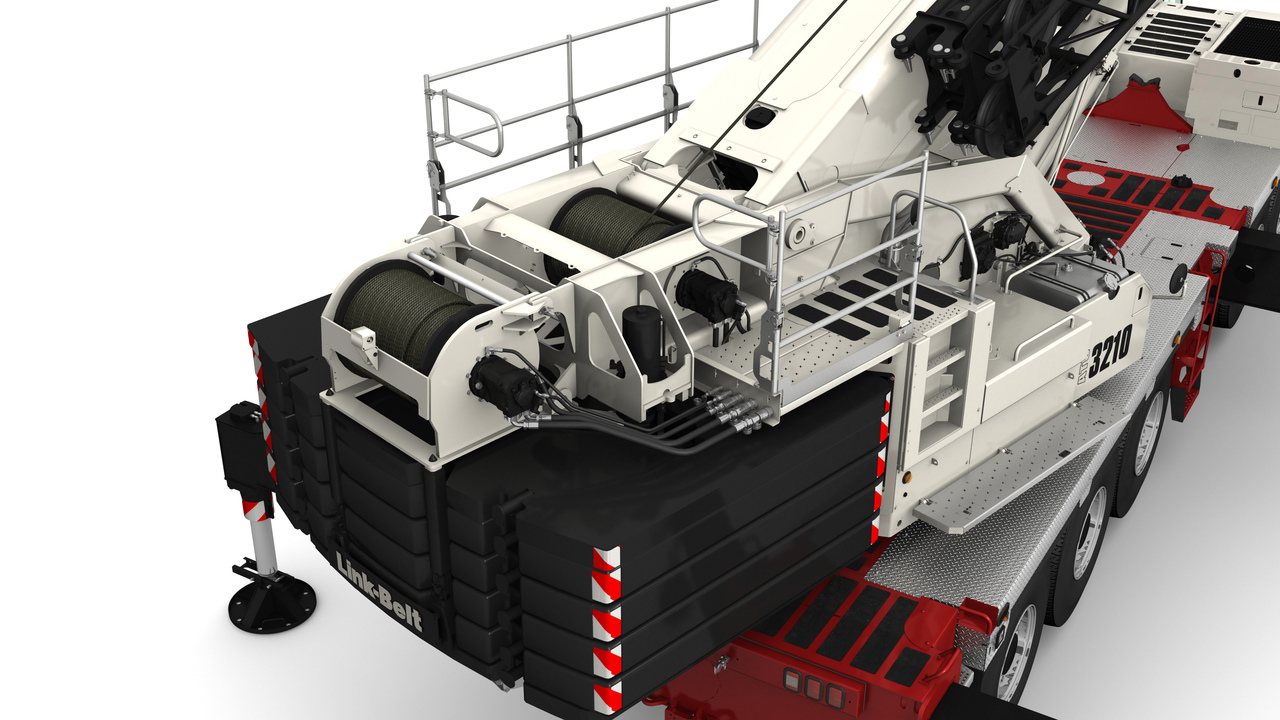

The pressure for hydraulics in the upper can be checked from one place. All connections and service points are centralised and easily accessible, the manufacturer said. Maximum axle load in that configuration is 20,000 pounds (9.07 tonnes).įor easier maintenance large doors are designed for good access to engines, filters and other regular maintenance points. At just under 145,000 pounds (65.78 tonnes) the ATC-3210 can transport in a three-axle dolly configuration, including three-piece hydraulic fly jib, auxiliary lifting sheave, hook block and ball, main and auxiliary winches. With maximum counterweight, rigging, matting, and fly jib extensions it can move in three 45,000 pound (20.41 tonne) truckloads, the manufacturer said. (9.98 tonnes) and they can be grouped with other components for transport. None of the counterweight slabs weigh more than 22,000 pounds. Also available are locking differentials between the wheels and between axles.

Suspension is Link-Belt’s Hydrogas and there is traction control with a mud and snow setting. Multiple steering modes are controllable from the single carrier cab and the drive/steer configuration is 10 x 6 x 10. Also available is a manual jib with four offset positions.Įasy road transport is a key factor so it is designed to meet the toughest transport laws in North America and its Cummins engine meets Tier IV final and EPA 2013 on-highway engine exhaust emission requirements, the manufacturer said. An optional three-piece bi-fold fly jib has hydraulic offset between 2 and 45 degrees. The 12 foot (3.7 m) heavy-lift fly has two-line, one-load lift procedures for concrete panel tilt-up work. Like the ATC-3275 the new crane’s upper engine is mounted transversely to maximise space for a stowable fly jib. Tip height for the fully extended main boom is 210.9 feet (64.3 m) and the maximum tip height, with all extensions and jib, is 326.7 feet (99.6 m). It is made in-house by Link-Belt in Kentucky using ultra high strength steel. The 200 foot (61 metre) fully curved profile boom is in six sections and there are seven extension modes to maximise capacities. It follows the first model, the ATC-3275, launched at the last ConExpo in 2011. The ATC-3210 is the second of the company’s ATs designed and built in the USA. It is aimed at the US market and will be launched at the March 2014 ConExpo show in Las Vegas. Brand new from crane manufacturer LinkBelt is the 210 US ton (185 tonne) capacity ATC 3210 all terrain on five axles.

0 kommentar(er)

0 kommentar(er)